90×6060×40×45 CM 108L Stainless Steel Salt Spray Corrosion Test Machine With 1φ,220V/50HZ

Application:

This machine for all kinds of metal material surface treatment, including coating, electroplating, organic and inorganic coating, anodizing, rust proof oil and preservative treatment test of its corrosion resistance, so as to establish the quality of the products.

The main technial parameters:

| Inner Box Size (L×W×H) |

60×45×40 cm |

| Outside Box Size(L×W×H) |

107×60×118 cm |

| Equipment Material |

Both inside & outside shell adopt imported P.V.C rigid plastic board, and tank cover uses imported transparent P.V.C. rigid plastic board |

| Temperature Range |

35°C~55°C |

| Temperature Fluctuations |

≤±0.5°C |

| Temperature Uniformity |

≤±2°C |

| Temperature Precision |

±1°C |

Test Chamber Temperature |

Salt Spray Method (NSS ACSS)35±1°C

Corrosion-resistant Testing Method(CASS)50±1°C |

| Saturated air Barrel Temperature |

Salt Spray Method (NSS ACSS)47±1°C

Corrosion-resistant Testing Method(CASS)63±1°C |

| Brine Temperature |

35°C±1°C |

| Spray Quantity |

1.0~2.0 ml / 80cm2 / hr |

| PH |

Salt Spray Method (NSS ACSS6.5~7.2)

Corrosion-resistant Testing Method(CASS)3.0~3.2 |

| Lab Volume |

108L |

| Brine Tank Capacity |

15L |

| Power |

1#, AC220V,10A |

| Multiple Safety Protection Devices |

Current discharge protection, over pressure protection, over temperature protection, over load fuse protection |

| Accessories |

Testing Salt/ Measuring tank/ Equipment each 1 set |

| Standard |

CNS: 3627, 3385, 4159, 7669, 8886;

JIS: D0201, H8502, H8610, K5400, Z2371;

ISO: 3768, 3769, 3770;

ASTM: B117, B268 |

Control system:

Temperature control:Control the chamber temperature, according to standard, salt test is 35°C, and corrosion test is 50°C.

Saturated air barrel temperature controller:Control the saturated air barrel temperature, salt test is 47°C, corrosion test is 63°C.

Timer:Adjustable, can set the time in 0.1s~9999hr free, shut down automatically when the time is over.

Running timer:Direct read 0-9999.9hr, record the whole work hours.

Heat sink temperature controller:Control the temperature of heat sink, Controller with temperature control of the testing machine laboratory environmental temperature changes around the difference is too large, also need to meet the adjustments, the setting method in the control box.

Salt test :Chamber temperature set 35°C, heat sink temperature set is 47°C(40°C-50°C).

Customize parts for Corrosion Test Chamber:

1. Inner chamber size

2. Inner chamber structure

3. PID programmable controller or PLC touch screen controller

Features :

1 Durable hard PVC construction, anti-corrosion, easy to clean.

2 Reservoirs with mixing system on stand.

3 Cabinet heated by water jacket, heating element from USA famous company.

4 Separate heating system, be apart from salt testing chamber to ensure accurate result and protect circuit.

5 Exposure zone lined with corrosion-resistant PVC sheets.

6 Clear cover allows viewing of test conditions.

7 Peaked cover prevents dripping of condensation onto samples.

8 Water seal and water level protection system.

9 Heated humidifying tower with air relief valve, adjustable tower tip to orient salt fog.

10 Automatic DI water fill to humidifying tower.

11 Digital temperature control and readouts.

12 Integral over-protection on all heaters.

13 Low water cut-off protection on humidifying tower.

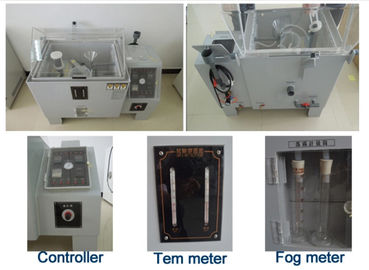

Product details:

Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!